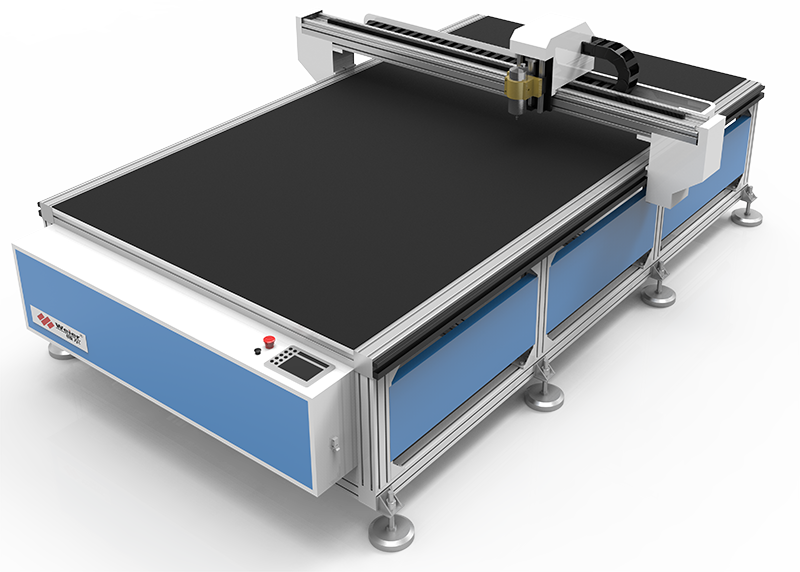

| Model | 1625 | Customizable (length*width) | |||

| Effective cutting size | 1600mm*2500mm |

Length: 800mm-15000mm width: 800mm-5000mm |

|||

| Feeding mode | manual | ||||

| Max cutting speed | 200mm/s | ||||

| Cutting precision | ±0.1mm | ||||

| Max cutting thickness | 50mm | ||||

| Data format | DXF, PLT, AI, etc. | ||||

| Transmission mode of data | data line, USB dis | ||||

| Materials fixation | Rubber roller, presser | ||||

| Power of spindle | 1.5KW/3KW | ||||

| Speed of spindle | 24000RPM | ||||

| Working voltage of main machine | AC220V/50HZ | ||||

| Air pump | 30L oil-free | ||||

| Rated power | 3KW-4KW | ||||

| Cutting tool | blade knife | ||||

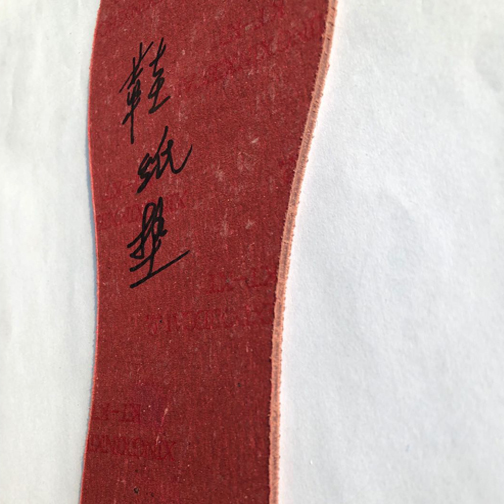

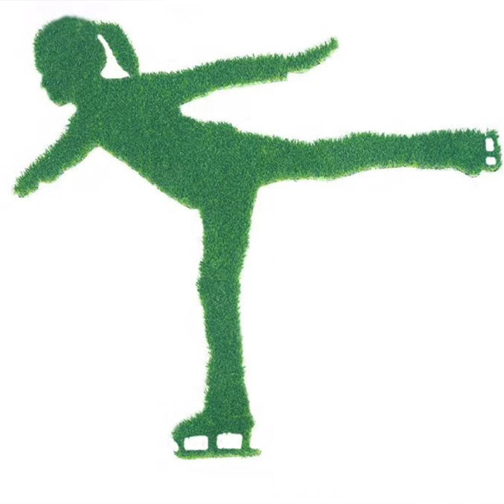

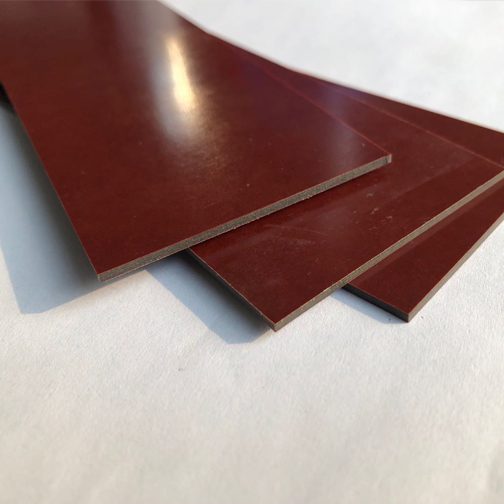

| Applicable materials | Car mat material, car trunk mat material, foamed PVC sheet, solid wood board, stone slate, cardboard, wire loop mat, artificial lawn, acrylic board, foaming board, etc | ||||

| Applicable industries | automotive interiors, printing and advertising, stone and wood engraving, carton proofing, furniture, packaging, etc. | ||||

The above data is for reference only and is subject to the actual product.

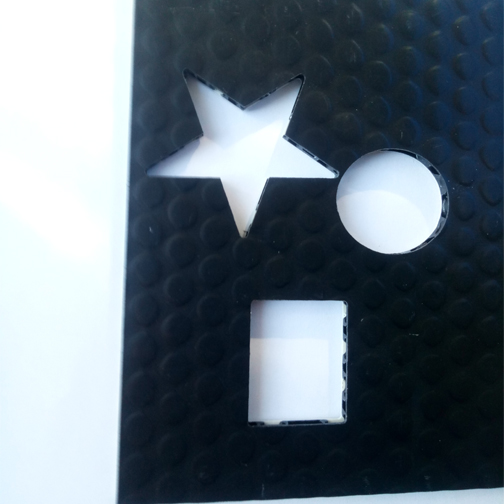

no need to make a die, directly import the electronic version

no pollution due to mechanical cutting

multi-machine working simultaneously supervised by one person

able to cut a variety of materials

Control system: The intelligent control system, PLC programming control system, work together with automatic typesetting and drawing software, to solve the special needs that cannot be processed by ordinary equipment

Motion system: precision helical gear rack, linear guide rail, high precision guide screw for Z axis, double motors for Y axis, precision running

Structural system: high strength welded frame, stable and no jitter when running

Pressing system: fully automatic pneumatic pressing, automatic and convenient.

With modern production workshop and necessary equipments

Nowadays, with the increasing development of science and technology, as a mature CNC equipment manufacturing enterprise, VIOOO Laser will continue to adhere to the business philosophy of “survive by quality, develop by reputation”, the management attitude of“rigor and pragmatism”, and the mission of improving production efficiency by technological innovation, to provide customers with better CNC equipment and solutions.

VIOOO Laser is on the way to success. You are on the way to success too accompanied by VIOOO Laser.