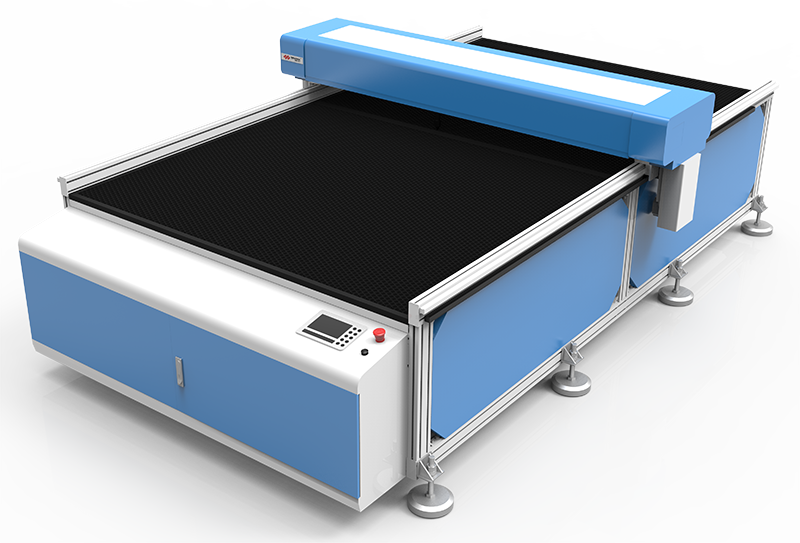

| Model | 1625 | 1825 | 2035 | 2240 | Customizable (length*width) |

| Effective cutting size | 1600mm*2500mm | 1800mm*2500mm | 2000mm*3500mm | 2200mm*4000mm |

Length: 800mm-15000mm width: 800mm-5000mm |

| Feeding mode | manual | ||||

| Max cutting speed | 400mm/s | ||||

| Cutting precision | ±0.1mm | ||||

| Max cutting thickness | 50mm | ||||

| Data format | DXF, PLT, AI, etc. | ||||

| Transmission mode of data | networking cable, data line, USB disk | ||||

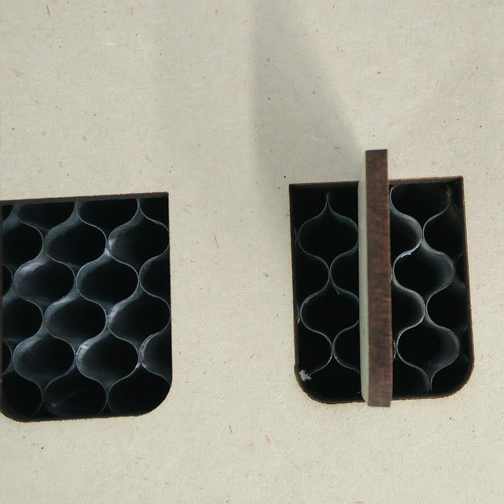

| Materials fixation | Blower adsorption | ||||

| Power of blower | 550W/1.1KW | ||||

| Working voltage of main machine | AC220V/50HZ | ||||

| Type of laser | CO2 | ||||

| Power of laser | 60W/80W/100W/130W/150W | ||||

| Operating environment | Temperature: 0~ 40°C Humidity: ≤80% non-condensing water, no dust or less dust | ||||

| Optional tools | Double head, triple head, double gantry, large CCD, small CCD, projection, ball-point pen, etc. | ||||

| Applicable materials | Non-metallic materials such as cloth, leather, cardboard, wood, composite materials | ||||

| Applicable industries | Garment, furniture, packaging, advertising and printing, automotive interiors, etc. | ||||

The above data is for reference only and is subject to the actual product.

laser cutting, no defect on the edge, with 0.1mm light spot, is non-contact processing,

which can cut a variety of complex graphics such as right-angle and punch.

This cutting machine requires only one person to operate from design to cutting.

Working with the typesetting software, the material utilization rate can be greatly improved.

competent to cut most non-metallic materials such as non-woven fabric, paper, nylon, foam, cotton, PTFE.

The design of fully enclosed flight light path protects the core optical devices from pollution, as well ensures the uniformity of the light spot effect of the whole cutting size, which has passed the CE certification.

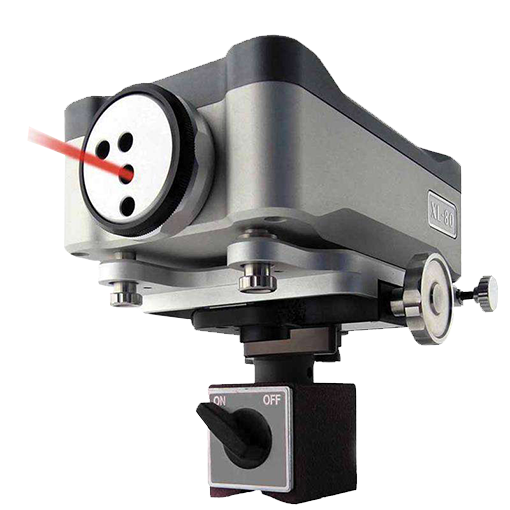

The positioning accuracy, repetition accuracy and reverse clearance of X, Y and Z axes of the machine were all detected by laser interferometer.

Control system: The intelligent control system, PLC programming control system, work together with automatic typesetting and drawing software, to solve the special needs that cannot be processed by ordinary equipment

Motion system: high quality guide rail, helical gear rack, double drives on Y axis, suitable for high precision machining

Structural system: Industrial aluminum alloy frame, no oxidation, no rust, no deformation, more durable, and more convenient for disassembly and assembly.

with modern production workshop and necessary equipments

Nowadays, with the increasing development of science and technology, as a mature CNC equipment manufacturing enterprise, VIOOO Laser will continue to adhere to the business philosophy of “survive by quality, develop by reputation”, the management attitude of“rigor and pragmatism”, and the mission of improving production efficiency by technological innovation, to provide customers with better CNC equipment and solutions.

VIOOO Laser is on the way to success.You are on the way to success too accompanied by VIOOO Laser.